Keenworth

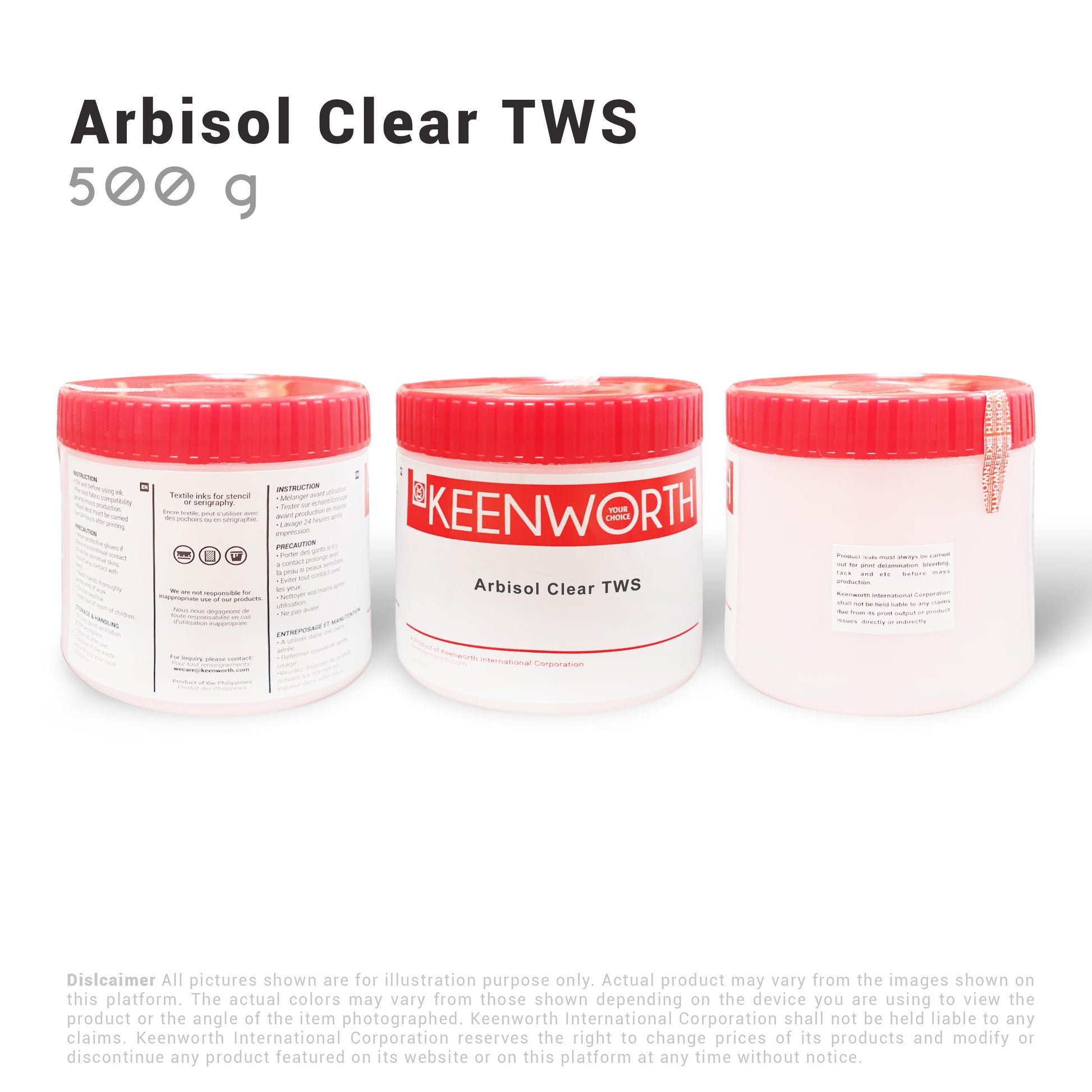

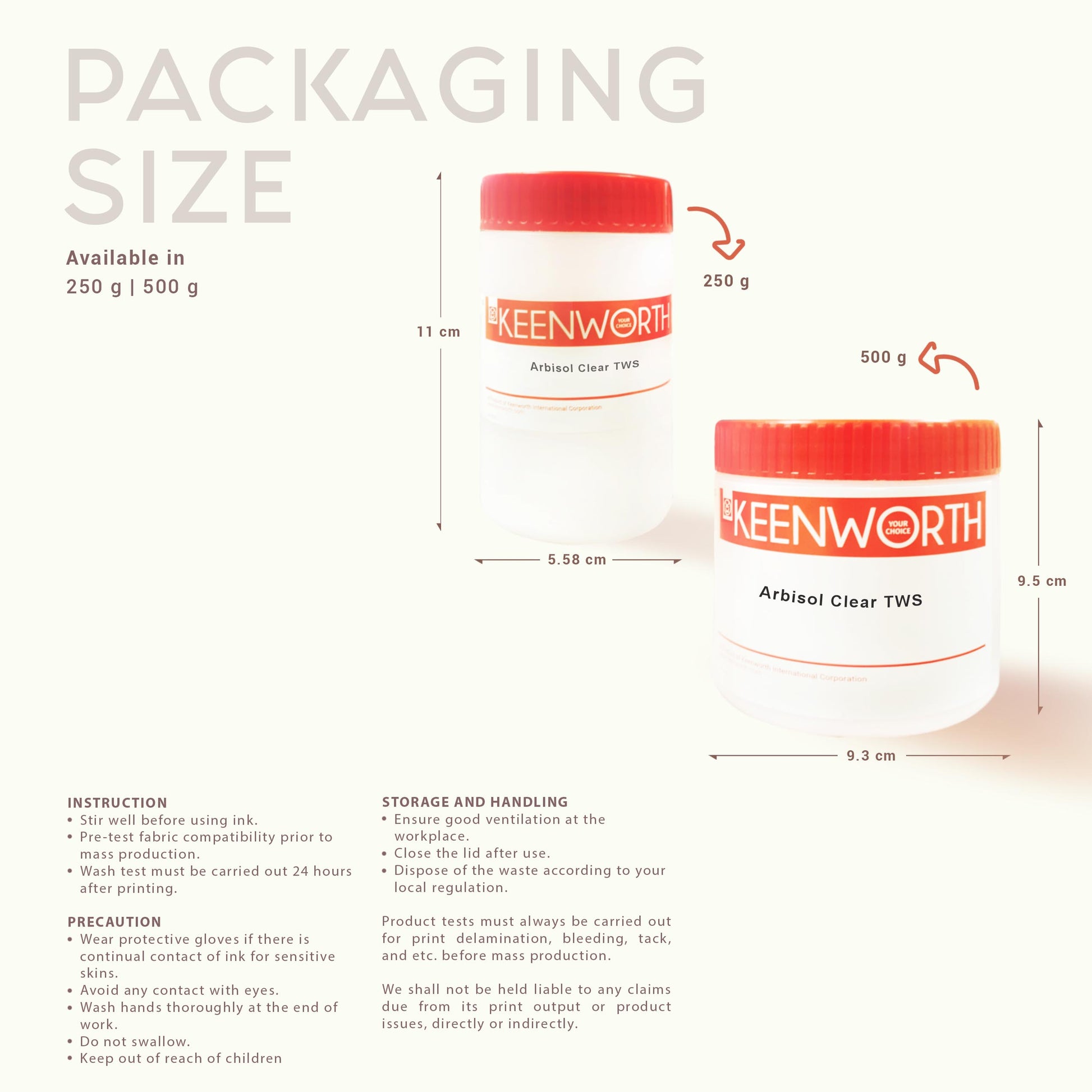

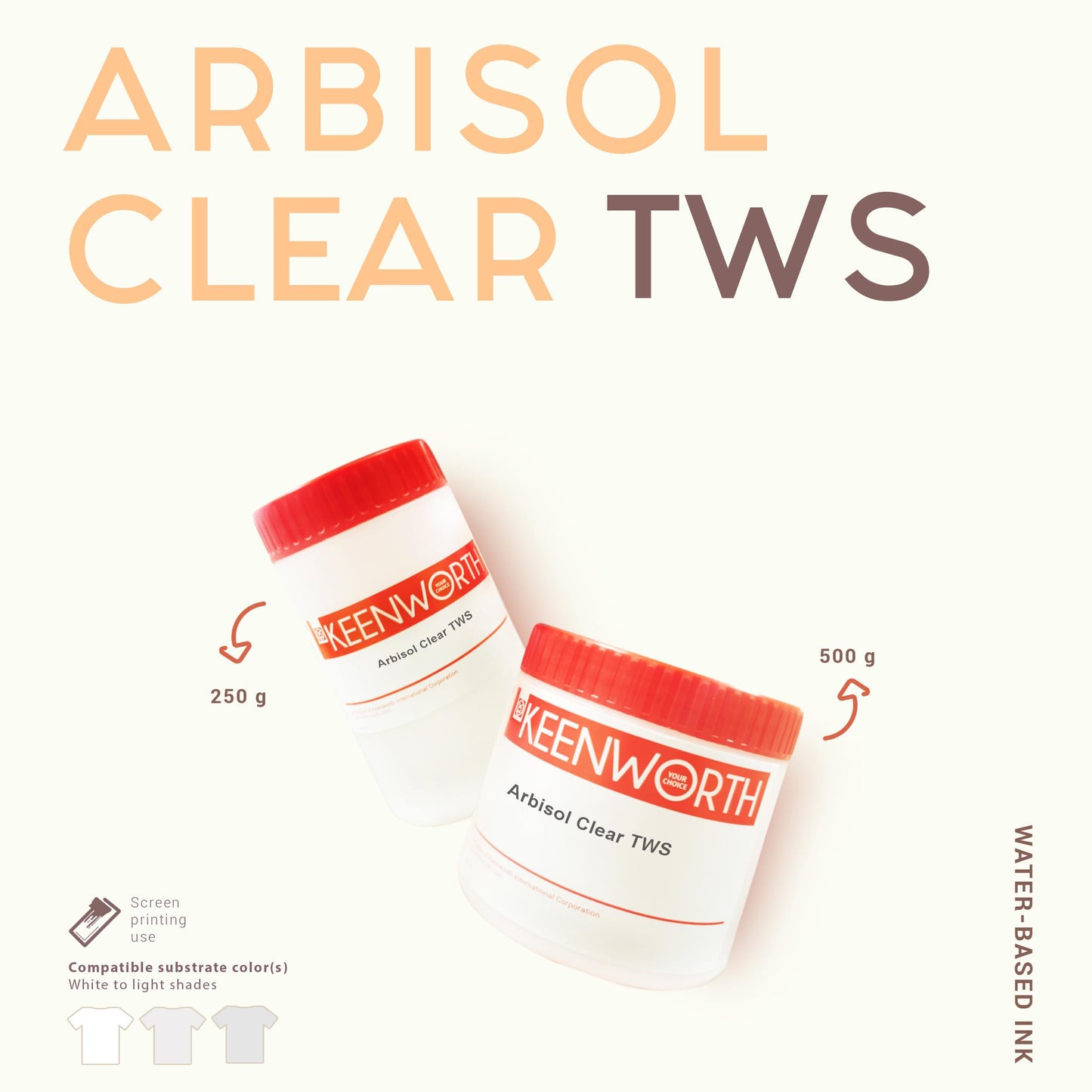

Arbisol Clear TWS

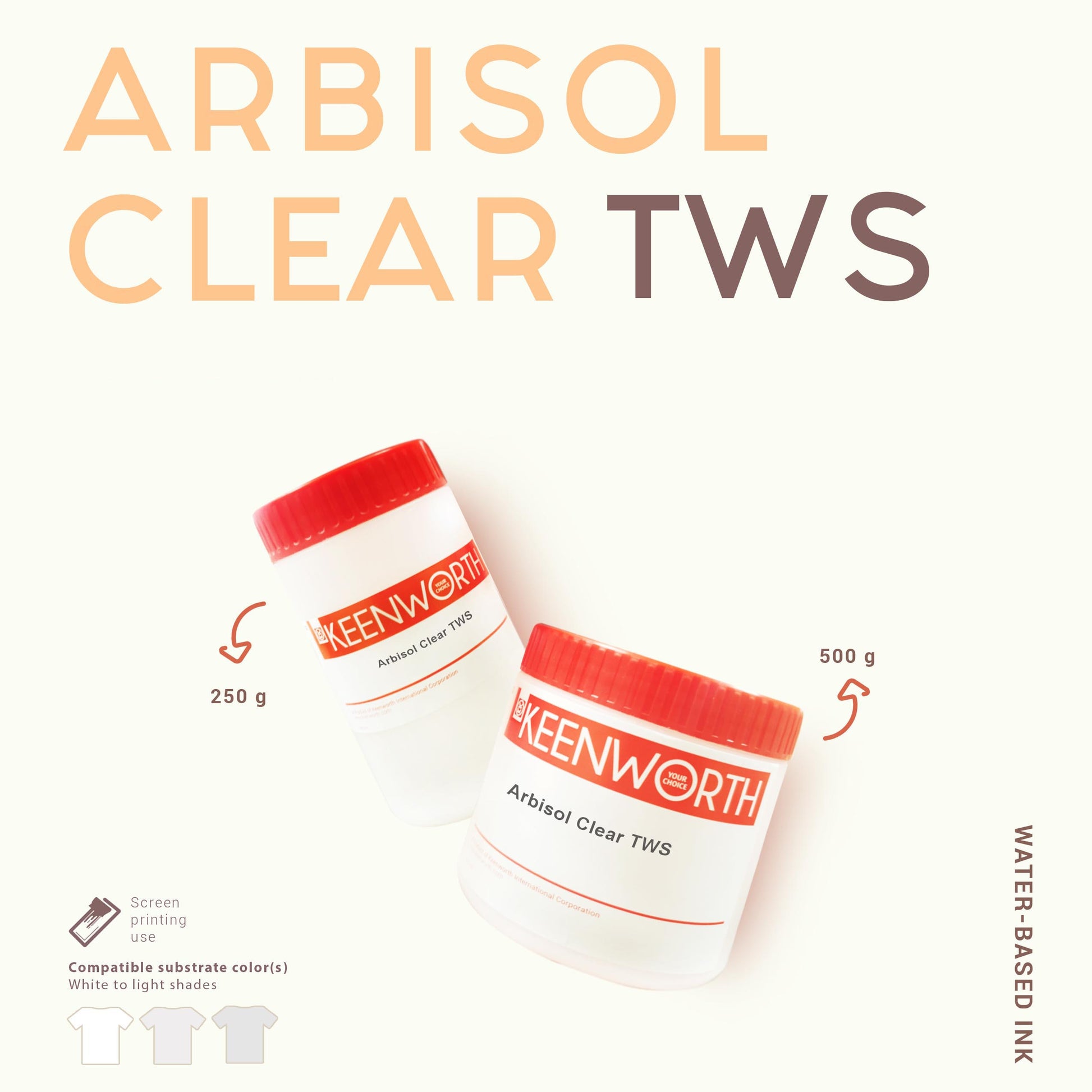

Arbisol Clear TWS

Arbisol Clear TWS is a transparent extender base ink that is optimally suited for achieving outstanding results on substrates ranging from smooth to textured substrates.

View full details

Additional Information